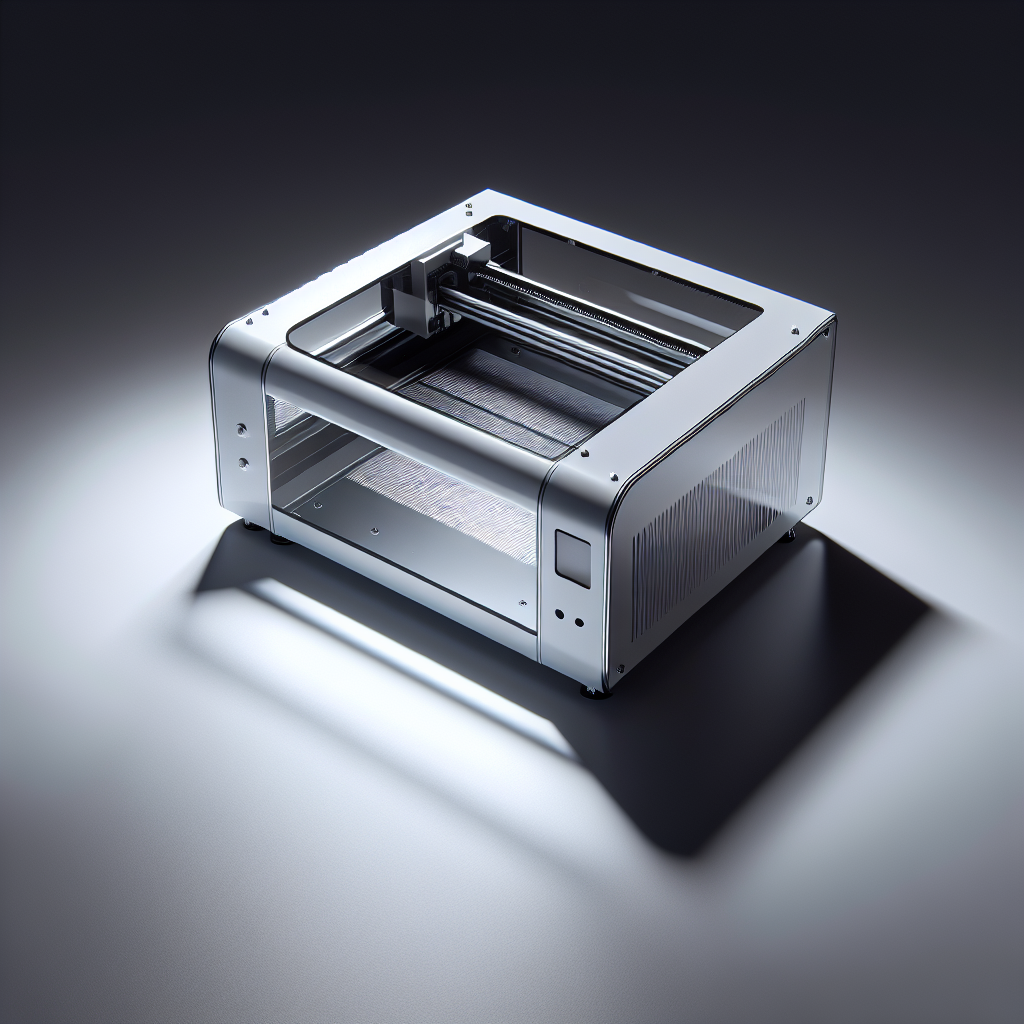

The Ultimate Guide to Laser Gun Engraving

Laser gun engraving has revolutionized the world of customization and precision craftsmanship. Whether you’re a hobbyist, an artist, or a professional, understanding how laser engraving works can open up endless possibilities for your projects. In this article, we’ll explore everything you need to know about laser gun engraving, from its benefits to its applications and how to choose the right machine for your needs.

What is Laser Gun Engraving?

Laser gun engraving is a process that uses a focused beam of light to etch or cut intricate designs onto various materials. Unlike traditional engraving methods, which rely on mechanical tools, laser engraving offers unparalleled precision and versatility. The laser gun engraving machine emits a high-powered beam that vaporizes or melts the material, creating detailed patterns without physical contact. This makes it ideal for delicate surfaces and complex designs.

One of the most significant advantages of laser engraving is its ability to work with a wide range of materials, including wood, metal, plastic, glass, and even leather. Whether you’re creating custom jewelry, decorative items, or industrial parts, laser gun engraving provides a solution that is both efficient and precise.

Benefits of Laser Gun Engraving

The benefits of laser gun engraving are numerous and make it a preferred choice for many professionals:

- Precision: Laser beams can create intricate designs with micron-level accuracy, ensuring that even the most detailed patterns are reproduced faithfully.

- Versatility: Compatible with various materials, laser engraving allows for creative freedom and adaptability across different industries.

- Speed: Compared to traditional methods, laser engraving is faster and more efficient, reducing production time significantly.

- No Physical Contact: Since there’s no mechanical contact during the process, the risk of damaging delicate materials is minimized.

- Eco-Friendly: Laser engraving produces minimal waste and does not require harmful chemicals, making it an environmentally sustainable option.

These benefits make laser gun engraving a versatile tool for both small-scale projects and large-scale industrial applications. Whether you’re looking to create personalized gifts or mass-produce custom parts, this technology offers a practical solution.

Applications of Laser Gun Engraving

Laser gun engraving has found its way into various industries due to its adaptability and precision. Here are some common applications:

- Jewelry Making: Engrave intricate designs on metals like gold, silver, or platinum to create unique jewelry pieces.

- Furniture Design: Add decorative patterns or personalized initials to wooden furniture for a custom touch.

- Industrial Marking: Use laser engraving to mark serial numbers, barcodes, or logos on metal components for identification and traceability.

- Crafts and Art: Create artistic engravings on glass, stone, or other materials to produce one-of-a-kind decorative items.

- Medical Devices: Engrave precise markings on medical instruments or implants for identification purposes.

These applications highlight the versatility of laser gun engraving and its ability to cater to diverse needs across different sectors. Whether you’re working in a creative field or an industrial setting, this technology can enhance your projects with precision and style.

How Does Laser Gun Engraving Work?

To understand how laser gun engraving works, let’s break down the process:

- Design Creation: Start by creating a digital design using specialized software. This design will guide the laser beam during the engraving process.

- Material Setup: Place the material you wish to engrave on the machine’s work surface. Ensure it is securely held in place to prevent movement during engraving.

- Laser Beam Activation: The laser beam, guided by the digital design, emits pulses of light that either vaporize or melt the material, creating the desired pattern.

- Post-Processing: After the engraving is complete, you may need to clean or finish the surface depending on the material and desired outcome.

This process ensures that even the most complex designs are executed with precision. The use of digital software allows for easy adjustments and customizations, making laser gun engraving a flexible tool for any project.

Choosing the Right Laser Gun Engraving Machine

Selecting the right laser gun engraving machine is crucial to achieving optimal results. Here are some factors to consider:

- Type of Material: Determine which materials you plan to engrave, as different machines are better suited for specific materials.

- Budget: Decide on your budget, as laser engraving machines vary in price depending on their features and capabilities.

- Machine Size: Consider the size of the projects you’ll be working on and choose a machine that offers enough workspace for your needs.

- Software Compatibility: Ensure the machine is compatible with the design software you plan to use.

If you’re looking for a reliable option, the laser gun engraving machine from [Your Brand] is designed to meet a wide range of needs. With advanced features and user-friendly operation, it’s perfect for both beginners and experienced users. Visit our website to learn more about this innovative tool.

Frequently Asked Questions About Laser Gun Engraving

Here are some common questions people have about laser gun engraving:

- Is laser engraving safe? Yes, when used correctly with proper safety precautions, laser engraving is a safe process. Always wear protective eyewear and ensure the machine is operated in a well-ventilated area.

- Can I engrave on all materials? While laser engraving works with many materials, some may require special settings or techniques. Research your material beforehand to ensure optimal results.

- How much does a laser engraving machine cost? The cost varies depending on the features and capabilities of the machine. Entry-level models can start at around $500, while high-end industrial machines may cost several thousand dollars.

By addressing these questions, you’ll be better equipped to navigate the world of laser gun engraving and make informed decisions for your projects.

Tips for Getting Started with Laser Gun Engraving

If you’re new to laser gun engraving, here are some tips to help you get started:

- Start Small: Begin with simple designs and small materials to familiarize yourself with the machine’s operation.

- Practice on Scrap Material: Use scrap material for practice runs to perfect your technique before working on your final project.

- Follow Safety Guidelines: Always adhere to safety protocols, including wearing protective gear and ensuring proper ventilation.

- Experiment with Materials: Try different materials to see how they react to the laser beam and achieve the desired effect.

By following these tips, you’ll be able to harness the full potential of laser gun engraving and create stunning, customized projects.

The Future of Laser Gun Engraving

As technology continues to advance, laser gun engraving is expected to become even more sophisticated. Innovations in laser technology are making machines more affordable, user-friendly, and capable of handling a wider range of materials. Additionally, the integration of artificial intelligence and machine learning is opening up new possibilities for automation and precision.

With these advancements, laser gun engraving will continue to play a vital role in industries ranging from art and crafts to manufacturing and medicine. As a versatile and efficient tool, it offers endless opportunities for creativity and innovation.

Conclusion

Laser gun engraving is a powerful tool that has transformed the way we approach customization and craftsmanship. Its precision, versatility, and efficiency make it an invaluable asset for both professionals and hobbyists. By understanding how it works, its benefits, and its applications, you can unlock new possibilities for your projects.

If you’re ready to take the plunge into the world of laser gun engraving, consider investing in a high-quality machine that suits your needs. With practice and creativity, you’ll be able to produce stunning, customized pieces that stand out. Start your journey today and discover the endless potential of this remarkable technology!