The Ultimate Guide to Home Steel Laser Cutters

Are you looking for a versatile tool that can help you bring your creative ideas to life? If so, you might want to consider investing in a home steel laser cutter. This innovative device has become increasingly popular among hobbyists, craftsmen, and professionals alike due to its precision, versatility, and ease of use. Whether you’re working on small-scale projects or larger industrial applications, a home steel laser cutter can be an invaluable addition to your workshop or studio. In this article, we’ll explore everything you need to know about these machines, including their benefits, features, and how they can revolutionize your work.

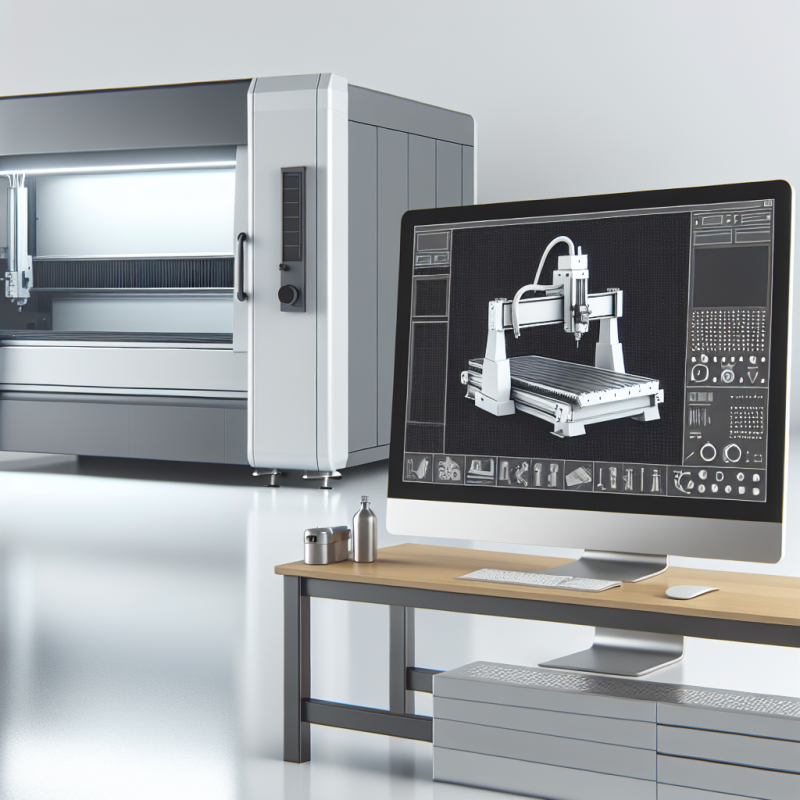

What Is a Home Steel Laser Cutter?

A home steel laser cutter is a machine that uses a highly focused laser beam to cut through various materials with extreme precision. Unlike traditional cutting tools, which rely on mechanical blades or saws, laser cutters use light to make clean, precise cuts without causing damage to the surrounding material. This makes them ideal for working with delicate materials like wood, plastic, leather, and even certain types of metal.

The machine operates by directing a laser beam through a series of lenses and mirrors, which focus the light into a tiny, intensely hot spot. This concentrated heat melts or vaporizes the material being cut, creating a clean edge with minimal burring or distortion. The process is controlled by a computer, which allows for intricate designs and patterns to be programmed and executed with ease.

If you’re wondering, “How does a home steel laser cutter compare to other cutting tools?” the answer lies in its precision and versatility. While traditional tools may leave rough edges or require multiple passes to achieve clean cuts, a laser cutter can handle these tasks in a single pass with exceptional accuracy. This makes it a favorite among artists, engineers, and hobbyists who value both speed and quality.

Why Should You Consider a Home Steel Laser Cutter?

There are numerous reasons why a home steel laser cutter might be the perfect tool for your needs. Here are just a few of the key benefits:

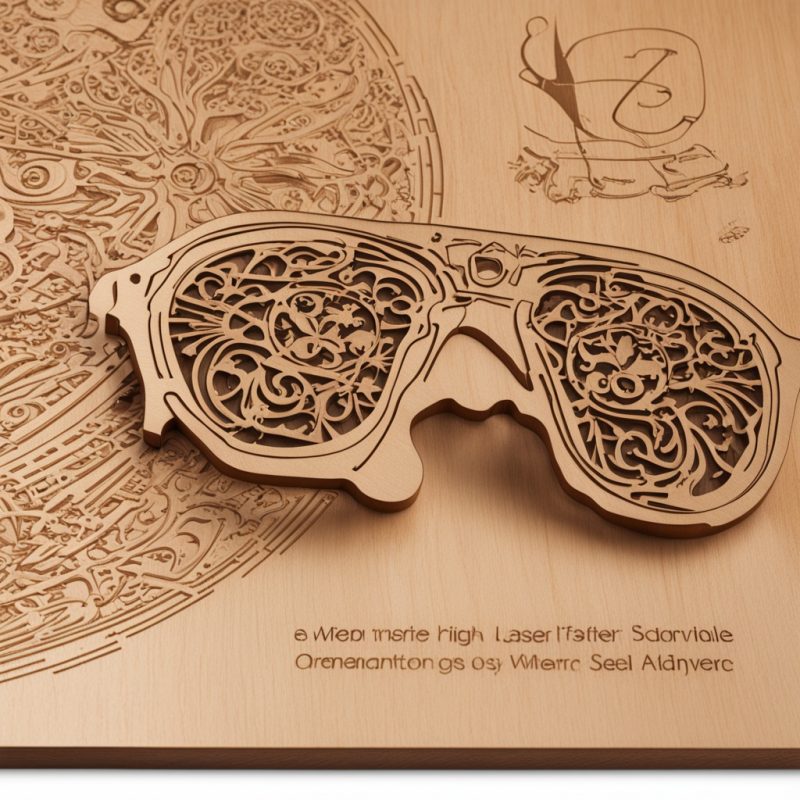

- Precision and Accuracy: The laser beam’s pinpoint focus ensures that even the most intricate designs can be cut with absolute precision.

- Versatility: Capable of cutting through a wide range of materials, including wood, plastic, leather, and metal, this machine is suitable for virtually any project you can imagine.

- Speed: Laser cutting is much faster than traditional methods, allowing you to complete projects in a fraction of the time.

- Ease of Use: Modern laser cutters are designed with user-friendly interfaces, making them accessible even for those who are new to the technology.

- Clean Cuts: Unlike mechanical cutting tools, which can leave rough edges or require additional sanding, laser cuts are smooth and finished right out of the machine.

If you’re asking yourself, “Is a home steel laser cutter worth the investment?” the answer is almost certainly yes. The versatility and precision of these machines make them an excellent choice for both casual users and professionals who demand high-quality results.

Features to Look For in a Home Steel Laser Cutter

When shopping for a home steel laser cutter, it’s important to consider the features that will best suit your needs. Here are some key factors to keep in mind:

- Laser Power: The power of the laser determines how thick or dense a material can be cut. For home use, a lower-power machine may suffice, but if you plan to work with thicker materials, you’ll need a more powerful unit.

- Cutting Area: Consider the size of your projects when selecting a laser cutter. A larger cutting area will give you more flexibility, but it may also be more expensive.

- Material Compatibility: Not all laser cutters are capable of cutting every material. Be sure to choose a machine that can handle the types of materials you plan to work with.

- User Interface: A user-friendly interface will make it easier to program and execute your designs, especially if you’re new to laser cutting.

- Maintenance and Support: Look for a machine that comes with good customer support and easy-to-access maintenance features.

If you’re still unsure about which features are most important, consider consulting reviews or reaching out to other users who have experience with the machines you’re considering. This can help you make an informed decision and choose a home steel laser cutter that meets your specific needs.

How to Use a Home Steel Laser Cutter

Using a home steel laser cutter is relatively straightforward, but there are a few steps you’ll need to follow to ensure the best results. Here’s a quick guide:

- Design Your Project: Use a computer-aided design (CAD) software or graphic design program to create your desired pattern or shape.

- Prepare the Material: Place the material you’ll be cutting on the machine’s bed. Ensure it is securely fastened and properly aligned with the laser beam.

- Program the Machine: Transfer your design to the laser cutter using the appropriate software. Most machines come with user-friendly interfaces that allow for easy programming and adjustments.

- Cut the Material: Once everything is set up, start the machine and watch as it cuts your design with precision and ease.

- Finish and Sand: After the cut is complete, remove any excess material or burrs from the edges. For a polished finish, you may want to sand or buff the edges slightly.

If you’re wondering, “How long does it take to learn how to use a home steel laser cutter?” the answer is that it depends on your familiarity with design software and cutting tools. However, most users find that they can get up to speed quickly with just a little practice.

Maintenance Tips for Your Home Steel Laser Cutter

To ensure your home steel laser cutter continues to perform at its best, it’s important to follow some basic maintenance tips. Here are a few key recommendations:

- Clean Regularly: Dust and debris can accumulate on the machine’s surfaces and inside the housing, so be sure to clean it regularly with a soft cloth.

- Check Laser Alignment: Periodically check the alignment of the laser beam to ensure it remains focused and accurate. Misalignment can lead to poor cuts or damage to the machine.

- Replace Consumables: Replace any worn-out or damaged parts, such as lenses or mirrors, promptly to maintain optimal performance.

- Follow Safety Guidelines: Always wear protective eyewear and follow the manufacturer’s safety guidelines when operating the machine. This will help prevent accidents and extend the life of your equipment.

If you’re asking yourself, “How often should I perform maintenance on my home steel laser cutter?” the answer is that it depends on how frequently you use the machine. However, a general rule of thumb is to clean and inspect the machine at least once every few months or after completing particularly large projects.

Frequently Asked Questions About Home Steel Laser Cutters

If you’re new to laser cutting, you may have some questions about how these machines work and whether they’re right for your needs. Here are answers to some of the most commonly asked questions:

- What materials can a home steel laser cutter cut?

These machines can cut through a wide range of materials, including wood, plastic, leather, and certain types of metal. Always check the machine’s specifications to ensure it can handle the materials you plan to use. - How easy is it to learn how to use one?

Most users find that they can get up to speed quickly with just a little practice. The user-friendly interfaces on modern machines make them accessible even for those who are new to laser cutting. - Are there any safety concerns I should be aware of?

Yes, it’s important to follow all safety guidelines when operating a laser cutter. This includes wearing protective eyewear and ensuring the machine is properly ventilated to avoid inhaling fumes from the cutting process. - How much do they cost?

The price of a home steel laser cutter can vary widely depending on its power, features, and capabilities. Entry-level machines may cost around $1,000, while more advanced models can range from $5,000 to $10,000 or more.

If you’re still unsure about whether a home steel laser cutter is the right choice for your projects, consider reaching out to other users or consulting online forums. This can help you gather more information and make an informed decision.

Conclusion

A home steel laser cutter is a powerful tool that can open up a world of creative possibilities for your projects. Whether you’re working on furniture, decorative items, or custom signage, these machines offer precision and versatility that are hard to match with traditional cutting tools.

By following the tips and guidelines outlined in this guide, you can make the most of your home steel laser cutter and achieve professional-quality results. So why wait? Start exploring the possibilities today and see how this amazing technology can transform your projects!

A home steel laser cutter is a versatile tool that offers numerous benefits for various creative and practical projects. Here’s an organized summary of its key aspects: