The Ultimate Guide to Fiber Laser Engraving Machines

Fiber laser engraving machines have revolutionized the world of precision cutting and engraving. These advanced tools combine speed, accuracy, and versatility to meet the demands of modern manufacturing and craftsmanship. Whether you’re working with metals, plastics, or other materials, a offers unparalleled performance. In this comprehensive guide, we’ll explore the features, benefits, and applications of these machines, as well as answer common questions to help you decide if one is right for your needs.

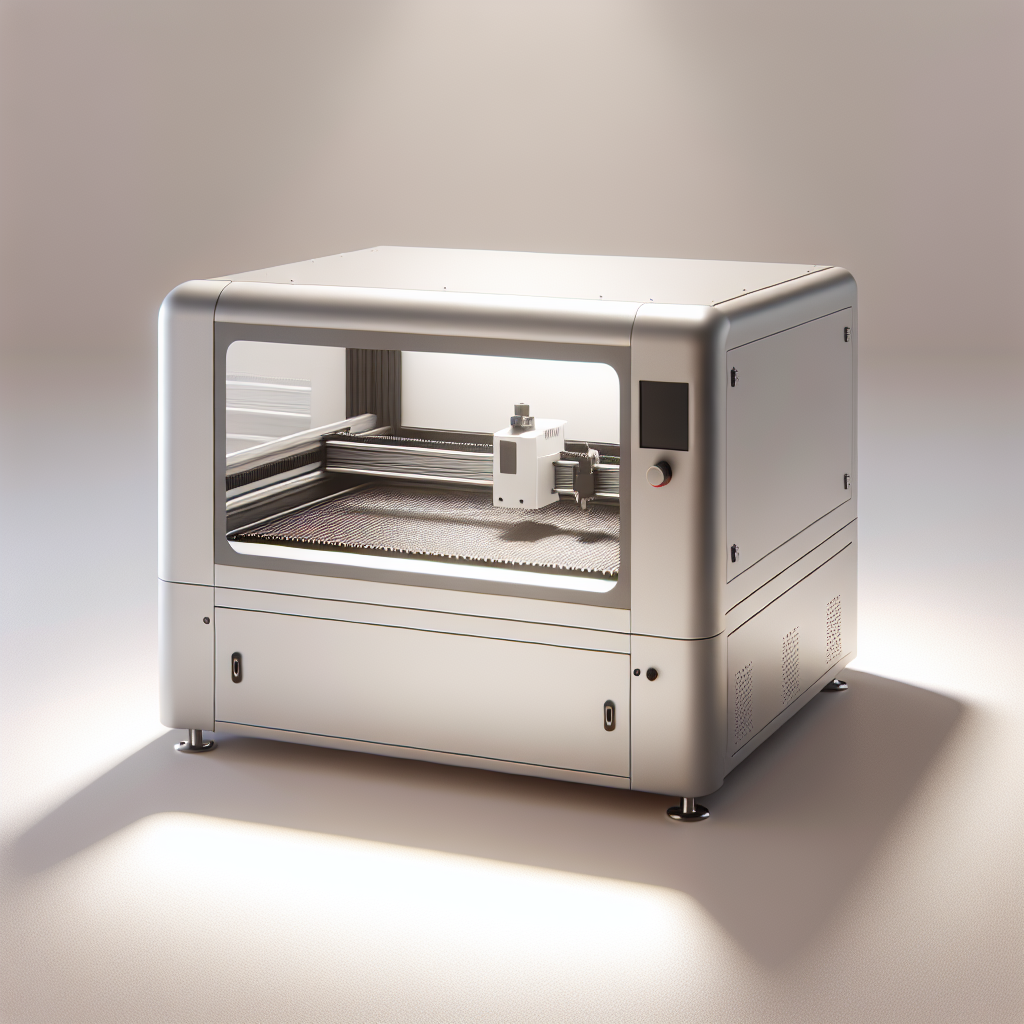

What Is a Fiber Laser Engraving Machine?

A fiber laser engraving machine uses a high-powered laser beam to cut or engrave materials with exceptional precision. Unlike traditional mechanical cutting methods, fiber lasers operate without physical contact, reducing wear and tear on the equipment while delivering cleaner cuts and engravings. The fiber laser technology is known for its efficiency, durability, and ability to work with a wide range of materials, making it a favorite among hobbyists, small businesses, and large-scale manufacturers alike.

The machine consists of several key components: the laser source, optics, worktable, control system, and software. The laser source generates the beam, which is then directed through mirrors or lenses to focus on the material being engraved or cut. The worktable holds the material in place, ensuring accurate positioning during the process. Advanced control systems and software allow users to program intricate designs and patterns, enabling high-speed production with minimal errors.

Advantages of Fiber Laser Engraving Machines

Fiber laser engraving machines offer numerous advantages over traditional methods:

- High Precision: The laser beam produces cuts and engravings with micrometer-level accuracy, ensuring flawless results even on complex designs.

- Versatility: Capable of working with various materials, including metals, plastics, wood, glass, and stone, these machines are suitable for a wide range of applications.

- Speed: Fiber lasers operate at high speeds, significantly reducing production time compared to manual or mechanical methods.

- No Physical Contact: Since the laser doesn’t touch the material, there’s no risk of wear and tear on the tool or damage to delicate surfaces.

- Ease of Use: Modern machines come with user-friendly interfaces and software, making them accessible even for those without extensive technical expertise.

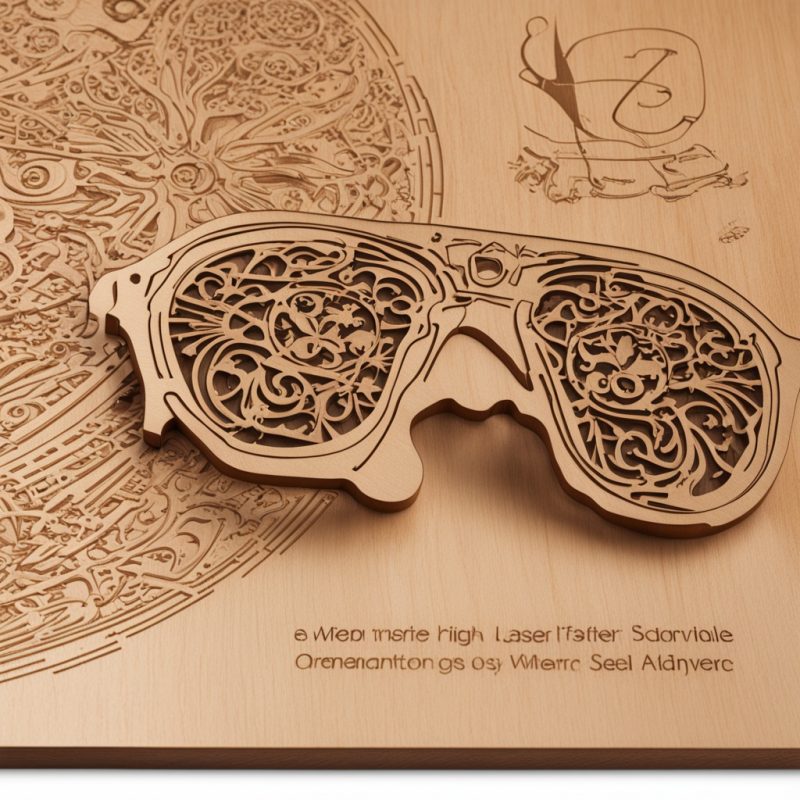

Applications of Fiber Laser Engraving Machines

Fiber laser engraving machines are used in numerous industries due to their versatility and precision. Some common applications include:

- Custom Engraving: Creating personalized items like jewelry, plaques, and nameplates with intricate designs.

- Circuit Board Production: Cutting and engraving printed circuit boards (PCBs) for electronics manufacturing.

- Glass and Stone Work: Etching patterns on glassware or gravestones for decorative or informational purposes.

- Furniture Making: Adding detailed carvings to wooden furniture pieces.

- Medical Devices: Engraving small, precise components used in medical equipment.

The ability to work with such a diverse range of materials makes fiber laser engraving machines an invaluable tool for businesses looking to expand their production capabilities.

How to Choose the Right Fiber Laser Engraving Machine

Selecting the appropriate machine depends on your specific needs and budget. Here are some factors to consider:

- Laser Power: Higher power lasers can handle thicker materials but may be unnecessary for lighter tasks.

- Material Compatibility: Ensure the machine is capable of working with the types of materials you’ll be using.

- Software and Controls: Look for user-friendly interfaces and robust software for creating and editing designs.

- Budget: Fiber laser engraving machines vary in price, so it’s important to find one that balances cost and functionality.

If you’re unsure about which machine to choose, consult with experts or read reviews to get a better understanding of your options. For instance, the is known for its reliability and ease of use.

Maintenance Tips for Fiber Laser Engraving Machines

Like any precision tool, fiber laser engraving machines require regular maintenance to ensure optimal performance. Follow these tips:

- Clean the Worktable: Regularly remove dust and debris from the worktable to maintain accuracy.

- Inspect Optics: Check lenses and mirrors for dirt or damage, as they can degrade laser performance over time.

- Update Software: Keep your machine’s software up-to-date to access new features and improvements.

- Replace Consumables: Replace worn-out components, such as belts or nozzles, promptly to avoid downtime.

Fiber Laser vs. Traditional Methods: Which Wins?

Fiber laser engraving machines offer several advantages over traditional methods. For example:

- Cleaner Cuts: Unlike mechanical cutting, fiber lasers leave no burrs or rough edges.

- Reduced Material Waste: The precise nature of laser cutting minimizes waste, lowering production costs.

- Faster Processing Times: High-speed operation reduces the time required to complete projects.

However, traditional methods may still be more cost-effective for certain applications or small-scale operations. It ultimately depends on your specific requirements and budget constraints.

Frequently Asked Questions

- 1. How much does a fiber laser engraving machine cost?

- 2. Can fiber lasers work with all materials?

- 3. Is it difficult to learn how to use one?

- 4. How often do I need to maintain the machine?

The cost varies depending on the model and features, ranging from $1,000 to over $100,000. Entry-level machines are suitable for hobbyists, while high-end models cater to industrial use.

While they can handle a wide range of materials, some substances like highly reflective metals or certain composites may require specialized settings or additional equipment.

No, modern machines come with intuitive software and guides, making them accessible even for beginners.

Maintenance frequency depends on usage. However, regular cleaning and inspections are recommended to ensure longevity and performance.

Conclusion

Fiber laser engraving machines represent a significant advancement in precision cutting and engraving technology. Their ability to deliver high-quality results with speed and versatility makes them an excellent investment for businesses looking to enhance their production capabilities. Whether you’re a small workshop owner or part of a large manufacturing facility, consider upgrading to a Chic Laser Engraver for unmatched performance and reliability.

If you’re ready to take the plunge into the world of fiber laser engraving, do your research and choose a machine that aligns with your specific needs. Happy crafting!