The Ultimate Guide to Fiber Laser Engravers: Precision, Efficiency, and Creativity

Fiber laser engravers have revolutionized the world of precision cutting and engraving. These advanced machines combine speed, accuracy, and versatility, making them an essential tool for industries ranging from manufacturing to art and design. If you’re new to the world of laser technology or looking to upgrade your current setup, this guide will walk you through everything you need to know about fiber laser engravers. Let’s dive in!

What Are Fiber Laser Engravers?

Fiber laser engravers are machines that use a focused beam of light to cut, engrave, or mark materials with exceptional precision. Unlike traditional mechanical tools, fiber lasers operate at the speed of light, enabling intricate designs and patterns that would be impossible to achieve manually. The fiber in fiber laser engravers refers to the type of laser source used, which is known for its high efficiency, reliability, and long service life.

These machines are widely used in industries such as woodworking, metalworking, jewelry making, and even electronics manufacturing. Whether you’re creating custom engravings on wood, metals, plastics, or glass, fiber laser engravers deliver unparalleled precision and consistency.

How Do Fiber Laser Engravers Work?

Fiber laser engravers work by generating a high-powered laser beam through a fiber optic medium. The beam is then focused onto the material being engraved, creating precise cuts or markings. The process involves three main components: the laser source, the optical system, and the control software.

- The laser source generates the light beam, which is amplified through fiber optic cables.

- The optical system focuses the beam onto the material, ensuring precise alignment and intensity.

- The control software allows users to design patterns, adjust settings, and control the engraving process in real-time.

This combination of advanced technology ensures that fiber laser engravers can handle a wide range of materials and projects with ease. Whether you’re working on a small-scale craft project or large-scale industrial production, these machines are designed to deliver consistent results.

Advantages of Fiber Laser Engravers

Fiber laser engravers offer numerous advantages over traditional engraving methods. Let’s explore some of the key benefits:

- Precision and Accuracy: Fiber lasers deliver micron-level precision, ensuring that even the most intricate designs are executed flawlessly.

- Speed: These machines operate at high speeds, reducing production time while maintaining quality. This makes them ideal for both small-scale projects and large-scale manufacturing.

- Versatility: Fiber laser engravers can work with a wide variety of materials, including wood, metal, plastic, glass, and even certain types of fabric.

- Low Maintenance: Unlike mechanical tools that require frequent replacements or adjustments, fiber lasers have a long service life and minimal maintenance requirements.

- Cost-Effective: Over time, fiber laser engravers can reduce operational costs due to their efficiency and low maintenance needs.

These advantages make fiber laser engravers a popular choice for professionals and hobbyists alike. If you’re wondering “Are fiber laser engravers worth the investment?”, the answer is yes—especially if you value precision, speed, and versatility in your projects.

Applications of Fiber Laser Engravers

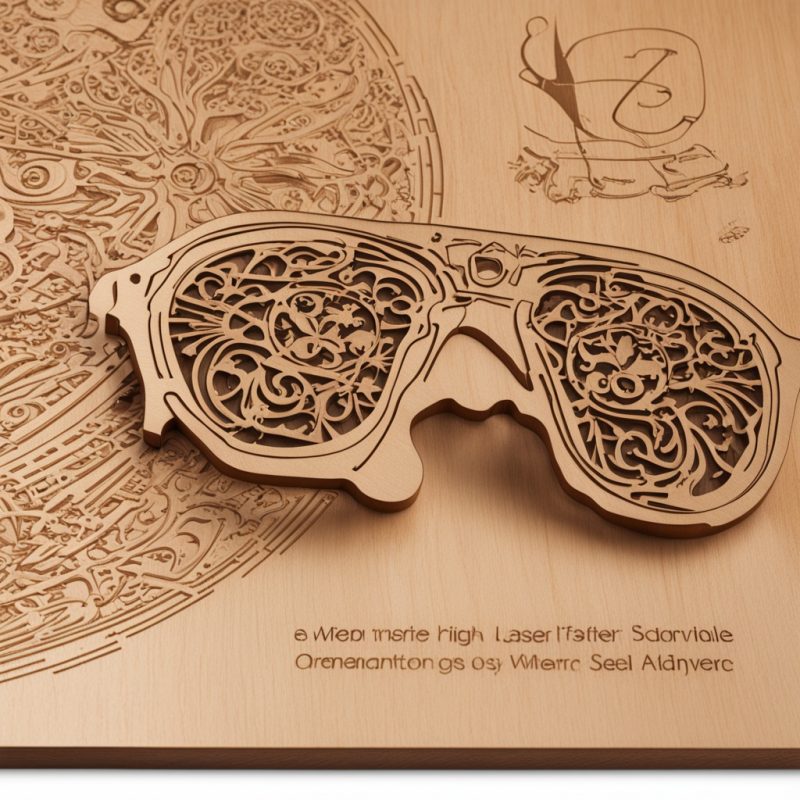

Fiber laser engravers are incredibly versatile and can be used in a wide range of applications. Here are some of the most common uses:

- Engraving: Create detailed designs, logos, or text on materials like wood, metal, and plastic.

- Cutting: Precision cutting for industrial parts, signage, or decorative items.

- Marking: Permanent markings on products for identification, branding, or quality control.

- Jewelry Making: Engraving intricate details on precious metals and gemstones.

- Electronics Manufacturing: Marking circuit boards or cutting complex shapes in PCBs.

Whether you’re working in a professional workshop or running a small-scale craft business, fiber laser engravers can help you achieve your creative and production goals with ease. For example, if you’re looking to “create custom jewelry engravings”, a fiber laser engraver is the perfect tool for the job.

Choosing the Right Fiber Laser Engraver

With so many options available on the market, selecting the right fiber laser engraver can be overwhelming. Here are some factors to consider when making your choice:

- Material Compatibility: Ensure that the machine is compatible with the materials you plan to work with. For example, some machines may not handle certain types of metal or glass effectively.

- Precision Requirements: If your projects require ultra-high precision, look for machines with higher resolution capabilities.

- Budget: Fiber laser engravers vary widely in price, so it’s important to set a budget and find a machine that offers the best value for your needs.

- Software Compatibility: Check if the machine comes with user-friendly software or if you need additional tools to design and control your projects.

If you’re still unsure about which model to choose, consider reading reviews or consulting with professionals who have experience using these machines. For example, asking “What is the best fiber laser engraver for small businesses?” could help you narrow down your options.

Maintenance and Safety Tips

While fiber laser engravers are low-maintenance compared to traditional tools, proper care is essential to ensure optimal performance and longevity. Here are some maintenance and safety tips:

- Cleanliness: Keep the machine clean by regularly removing dust or debris that may accumulate on the optical components.

- Lens Care: Avoid touching the lenses with bare hands, as oils from your skin can cause damage. Use a soft cloth and cleaning solution when necessary.

- Safety Glasses: Always wear safety glasses when operating the machine to protect your eyes from laser exposure.

- Adequate Ventilation: Ensure that the workspace is well-ventilated, especially when engraving materials that produce fumes or particulates.

By following these simple guidelines, you can maximize the lifespan of your fiber laser engraver and maintain its performance over time. Remember, “safety first” when working with powerful tools like these.

Frequently Asked Questions

If you’re new to the world of fiber laser engravers, you might have several questions. Here are some common FAQs:

- Q: Can fiber laser engravers cut through metal?

A: Yes, many fiber laser engravers are capable of cutting and engraving various types of metal, including steel, aluminum, and stainless steel. - Q: Are fiber lasers safe to use?

A: When used properly with safety precautions in place, fiber lasers are safe. Always follow the manufacturer’s guidelines and wear protective gear. - Q: How much do fiber laser engravers cost?

A: Prices vary widely depending on the machine’s specifications and capabilities. Entry-level models can start around $1,000, while high-end industrial machines may cost tens of thousands of dollars.

If you have more specific questions or need advice tailored to your project, don’t hesitate to reach out to experts or consult online forums for guidance.

Conclusion

Fiber laser engravers are powerful tools that offer precision, versatility, and efficiency in a wide range of applications. Whether you’re a professional craftsman, an industrial manufacturer, or a hobbyist looking to explore new creative possibilities, these machines can help you achieve your goals with ease.

If you’re ready to take the plunge and invest in a fiber laser engraver, be sure to do your research and choose a machine that best fits your needs. With proper care and maintenance, your fiber laser engraver will serve you well for years to come. Happy creating!