The Ultimate Guide to CNC Laser Cutters

CNC laser cutters have revolutionized the way we approach precision cutting and engraving in various industries. Whether you’re a hobbyist, an artist, or a professional fabricator, these machines offer unparalleled accuracy and versatility. In this article, we’ll explore everything you need to know about CNC laser cutters, including their features, benefits, applications, and how they can transform your projects. Let’s dive in!

What is a CNC Laser Cutter?

A CNC laser cutter (Computer Numerical Control) is a machine that uses a high-powered laser to cut or engrave materials with extreme precision. Unlike traditional cutting methods, CNC laser cutters are controlled by computer software, allowing for intricate designs and repetitive tasks to be executed with consistency. They are widely used in industries such as woodworking, metal fabrication, electronics, and even artistic creation.

These machines are perfect for both small-scale projects and large production runs. For instance, if you’re looking to create custom signs, logos, or decorative items, a CNC laser cutter can handle the task with ease. The machine’s ability to work with a variety of materials, including wood, metal, plastic, and glass, makes it an invaluable tool for many applications.

Key Features of CNC Laser Cutters

What sets CNC laser cutters apart from other cutting tools? Let’s take a look at their key features:

- Laser Precision: The use of lasers ensures that cuts are clean, precise, and free from the deformation often caused by mechanical cutting methods.

- Versatility: These machines can work with a wide range of materials, making them suitable for diverse projects.

- Computer-Controlled: The integration of CNC technology allows for complex designs and patterns to be programmed and executed effortlessly.

- Speed: Modern CNC laser cutters are designed for high-speed operation, reducing production time without compromising quality.

- User-Friendly: Many models come with intuitive software interfaces, making them accessible even to those who are new to CNC technology.

These features make CNC laser cutters a must-have tool for anyone looking to achieve professional-grade results in their projects.

Benefits of Using a CNC Laser Cutter

The advantages of using a CNC laser cutter are numerous. Let’s explore some of the key benefits:

- Precision and Accuracy: The laser beam ensures that cuts are made with extreme precision, minimizing waste and maximizing material utilization.

- Time Efficiency: Once programmed, CNC laser cutters can execute tasks quickly, reducing the overall production time.

- Versatility in Materials: These machines can work with various materials, including wood, metal, plastic, and glass, making them suitable for a wide range of applications.

- Cost-Effective: By reducing material waste and enabling high-speed production, CNC laser cutters help lower operational costs in the long run.

- Customization: The ability to create intricate designs and patterns allows for unlimited creativity and customization options.

These benefits make CNC laser cutters an excellent investment for businesses and individuals alike, offering both efficiency and flexibility in their operations.

Applications of CNC Laser Cutters

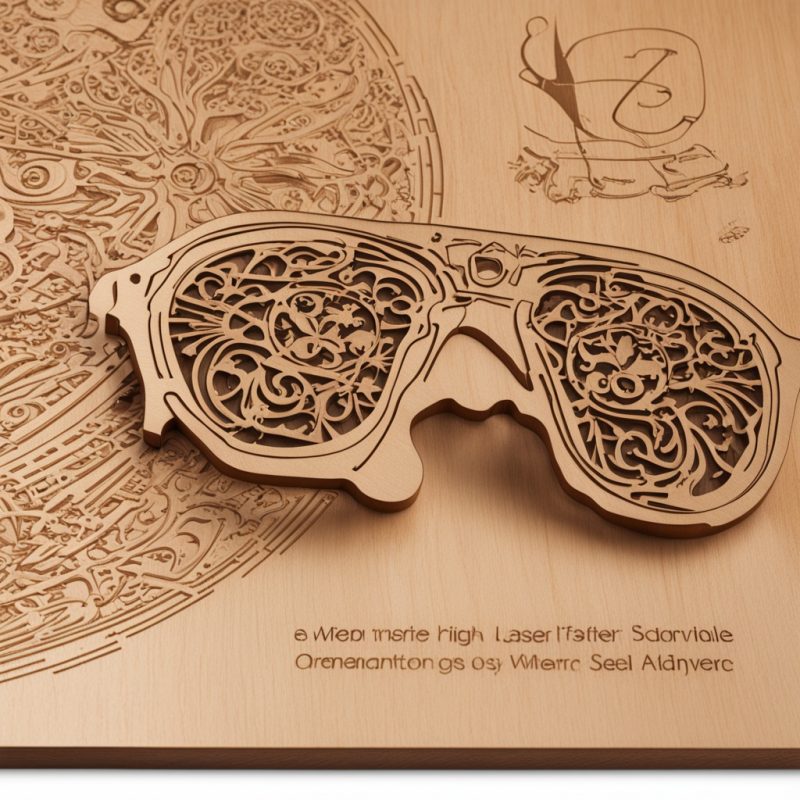

The versatility of CNC laser cutters means they can be used in a variety of industries. Here are some common applications:

- Woodworking: Engraving intricate designs, cutting patterns, and creating custom furniture pieces.

- Metal Fabrication: Cutting and engraving metal sheets for automotive parts, decorative items, and industrial components.

- Electronics: Precision cutting of circuit boards and other electronic components.

- Signage: Creating custom signs, logos, and branding materials with high precision.

- Artistic Creation: Engraving glass,, and other materials to produce unique artistic pieces.

The applications of CNC laser cutters are limited only by your imagination. Whether you’re working on a small-scale project or a large production run, these machines can handle the task with ease.

Choosing the Right CNC Laser Cutter

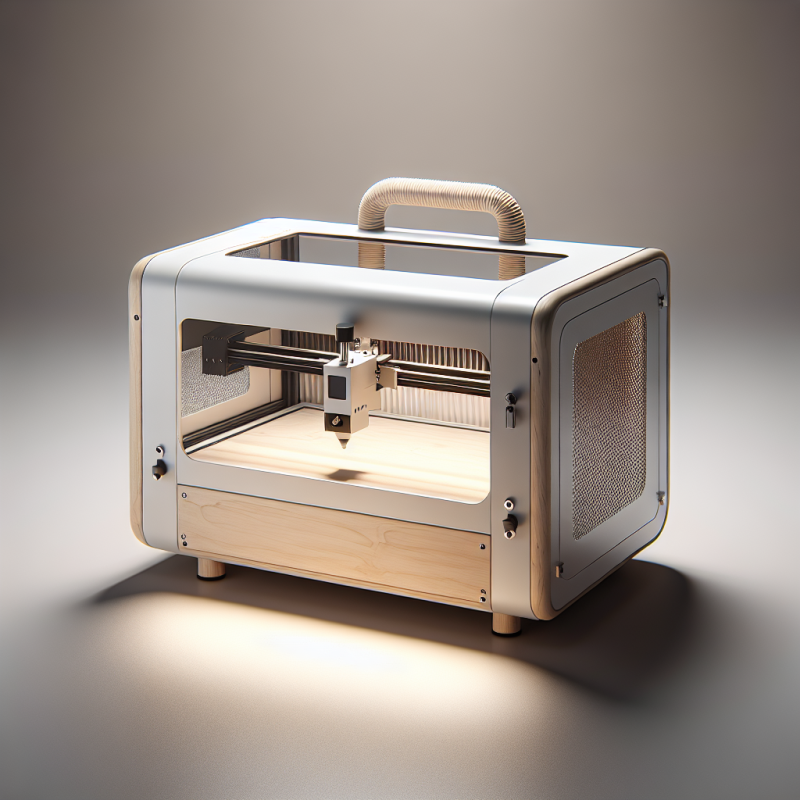

If you’re considering investing in a CNC laser cutter, it’s essential to choose the right machine for your needs. Here are some factors to consider:

- Material Compatibility: Determine the types of materials you’ll be working with, as this will influence the type of laser and machine required.

- Budget: CNC laser cutters vary in price, so it’s important to set a budget that aligns with your needs and expectations.

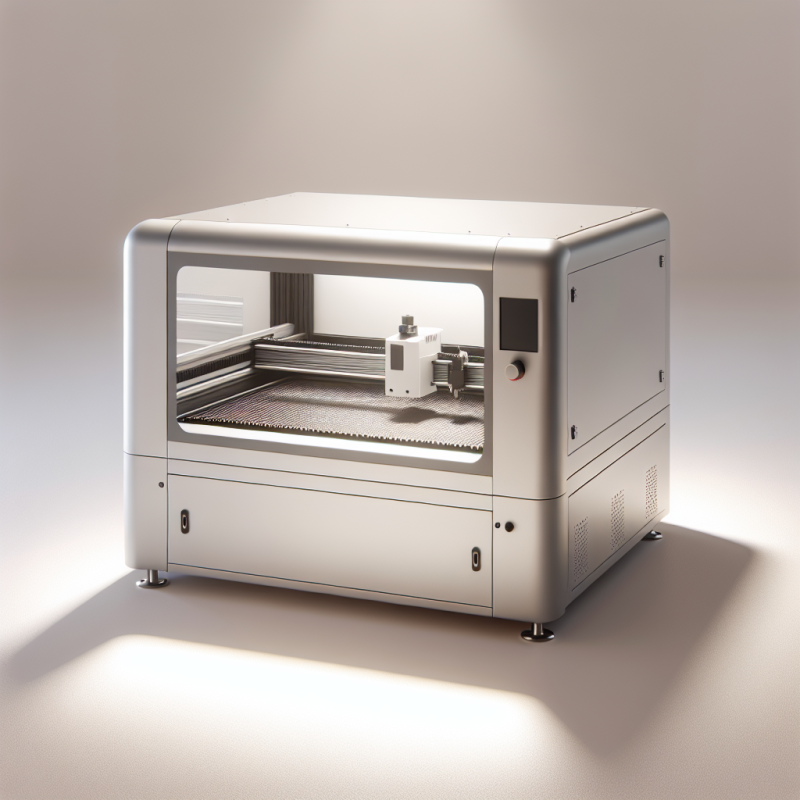

- Size and Capacity: Consider the size of the projects you’ll be working on and choose a machine with appropriate bed dimensions and power output.

- Software Compatibility: Ensure that the machine’s software is compatible with your existing design tools and operating system.

- After-Sales Support: Look for manufacturers or suppliers who offer reliable customer service and technical support.

By carefully evaluating these factors, you can select a CNC laser cutter that meets your specific requirements and provides long-term value.

Tips for Using CNC Laser Cutters Effectively

To get the most out of your CNC laser cutter, here are some tips to keep in mind:

- Proper Setup: Always ensure that the machine is properly set up and calibrated before starting a project.

- Material Preparation: Clean and prepare your materials adequately to achieve optimal cutting results.

- Design Optimization: Use design software to optimize your patterns and reduce waste during the cutting process.

- Regular Maintenance: Perform routine maintenance on your machine to ensure it continues to operate at peak performance.

- Safety First: Always follow safety protocols when operating a CNC laser cutter, including wearing protective gear and ensuring proper ventilation.

By following these tips, you can maximize the efficiency and longevity of your CNC laser cutter while achieving outstanding results in your projects.

Frequently Asked Questions About CNC Laser Cutters

If you’re new to CNC laser cutters, you might have some questions. Here are answers to some common FAQs:

- What materials can a CNC laser cutter work with?

Most CNC laser cutters can work with wood, metal, plastic, and glass. However, compatibility may vary depending on the machine’s specifications. - Is it difficult to learn how to use a CNC laser cutter?

While there is a learning curve, many modern CNC laser cutters come with user-friendly software that simplifies the process. With practice, you can become proficient in operating these machines. - How much does a CNC laser cutter cost?

The cost of a CNC laser cutter varies widely depending on its size, power, and features. Entry-level models can range from $1,000 to $5,000, while industrial-grade machines may cost upwards of $10,000 or more. - Can a CNC laser cutter be used for both cutting and engraving?

Yes, CNC laser cutters are capable of both cutting and engraving, making them highly versatile tools for various applications.

These answers should help you better understand the capabilities and limitations of CNC laser cutters.

The Future of CNC Laser Cutters

As technology continues to advance, so does the capability of CNC laser cutters. Future developments may include even higher precision, faster cutting speeds, and greater integration with other technologies like AI and IoT. This evolution promises to further enhance the efficiency and versatility of these machines, making them indispensable in industries across the globe.

Whether you’re a hobbyist or a professional, embracing CNC laser cutter technology can open up new possibilities for your projects. With their precision, versatility, and adaptability, these machines are sure to remain a cornerstone of modern manufacturing and craftsmanship for years to come.