“

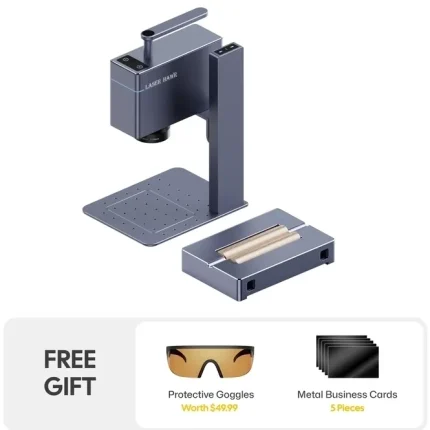

Introducing the LaserHawk LX1 Series, the ultimate solution for precision wood laser cutting and engraving. Designed to meet the needs of both hobbyists and professionals, this state-of-the-art laser cutter is the best laser cutter for small business and home use. Whether you’re crafting intricate designs or producing high-quality engravings, the LaserHawk LX1 Series delivers unmatched performance and reliability.

With its advanced laser cutter technology, the LaserHawk LX1 Series offers a seamless laser cutter service experience. Its user-friendly interface and robust construction make it the perfect choice for those seeking precision and efficiency. From custom woodwork to personalized gifts, this machine is your go-to tool for all your creative projects.

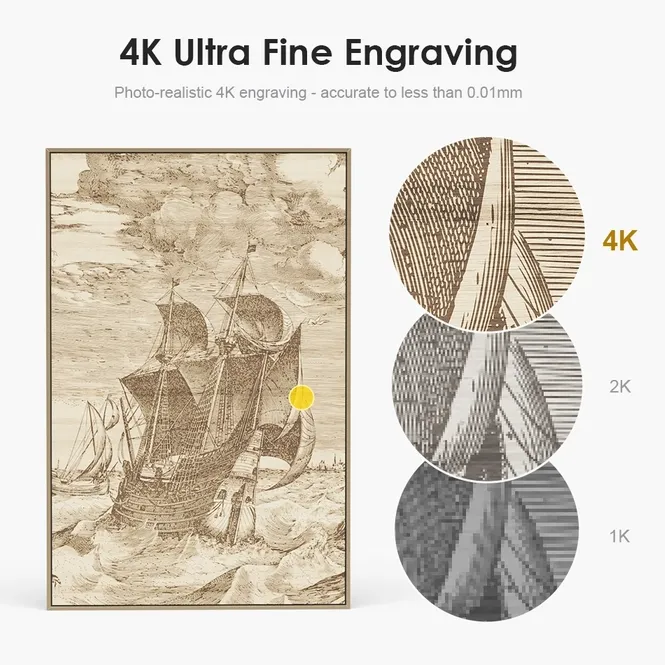

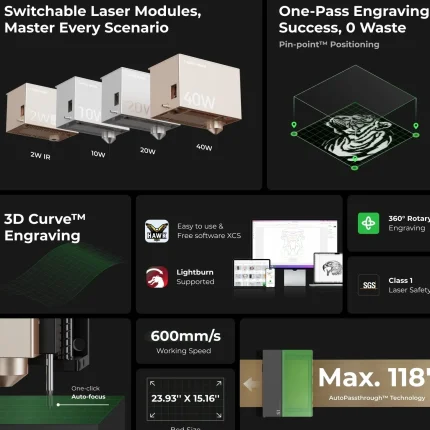

- High Precision Cutting: Achieve intricate designs with pinpoint accuracy, perfect for detailed woodwork and engraving.

- Versatile Applications: Ideal for a wide range of materials, including wood, acrylic, leather, and more.

- Compact Design: Space-saving and portable, making it the best laser cutter for small business setups and home workshops.

- User-Friendly Interface: Easy-to-use controls and software ensure a smooth operation for beginners and experts alike.

- Durable Construction: Built to last with high-quality materials, ensuring long-term reliability and performance.

Transform your creative vision into reality with the LaserHawk LX1 Series. Experience the power of laser cutter laser technology and elevate your craftsmanship to new heights. Whether you’re a small business owner or a DIY enthusiast, this machine is your ultimate partner in precision and creativity.

Don’t settle for less—choose the LaserHawk LX1 Series and discover why it’s the best laser engraver for home and professional use. Order now and take the first step towards revolutionizing your woodworking and engraving projects!

More you like:

Best laser engraver ✓ Laser cutter engraver✓Laser engraving machines✓LaserHawk LH1 Pro | Wood laser cutter✓Best laser engravers for home✓Laser engrave LaserHawk LX1 Series | Laser engraver machine✓Laser for engraving machine✓Laser cutter and engraver✓LaserHawk LH4 | Laser for engraving machine✔ Laser engraver for wood✔ Hawk P2S CO2 cutter laser | Xtool laser engraver ✔Laser engraver machine ✔Hawk F1 IR+DIODE | Laser cutter and engraver ✔Laser engraver for metal ✔Hawk S1 Enclosed Diode Laser Cutter | Laser engraving machine✓Laser cutter and engraver✓Laser engravers✓Diode Laser Engraver✓Laserhawk LH5 | Best laser engraver ✓ Laser cutter engraver✓Laser engraving machines✓LaserHawk LH1 Pro | Xtool laser engraver ✔Laser engraver machine ✔Hawk F1 IR+DIODE | Laser engraving✓Laser cutter machine✓Laser engraver engraving machine✓LaserHawk LH2

Robert Kim –

Laser engraver delivers exceptional precision & stunning results. Software is intuitive, and operations are seamless. Fast engraving boosts productivity. Solid build, highly reliable. 5 stars!

Eduardo Anderson (verified owner) –

**Laser Engraver Experience Review**

—

**Specific Project Experience: Promotional Products**

– **Materials Utilized:** The laser engraver was primarily used on stainless steel and acrylic for promotional items, such as engraved pens and name tags. These materials were chosen for their durability and aesthetic appeal.

– **Material Behavior:** Stainless steel required precise power settings to avoid discoloration, while acrylic needed careful handling to prevent cracking during engraving. The machine’s ability to adjust settings for each material was crucial for achieving consistent results.

– **Unique Challenges & Solutions:** One challenge was warping of acrylic sheets during the engraving process. To address this, I implemented a cooling system by periodically pausing the laser to allow the material to cool down, preventing distortion and ensuring smooth engravings.

—

**Technical Performance: Precision & Software**

– **Power Settings:** The engraver’s adjustable power settings were essential for different materials. Stainless steel needed higher power for deep engravings, while lower settings sufficed for acrylic, allowing fine details without surface damage.

– **Precision in Intricate Designs:** The laser’s high precision enabled the creation of complex patterns and logos on promotional items, ensuring each product was unique and visually appealing.

– **Software & Features:** Using CorelDRAW, I programmed custom designs with ease. The machine’s vector cutting feature was particularly useful for creating intricate shapes and cutouts in acrylic, enhancing the final product’s aesthetics.

—

**Summary:**

The laser engraver proved invaluable for producing high-quality promotional items, offering versatility across materials and precise detailing. By overcoming challenges like material warping and utilizing advanced software features, the machine significantly improved project outcomes, making it a key tool in my design workflow.

Hiroshi Jones –

“This laser engraver exceeds expectations! Impressive precision and detail in every carve. Easy-to-use software, smooth operation, and swift engraving make it a top choice. Highly recommend!”