Alright, let me try to figure out what the user is asking for here. They want a product description for a laser cutter machine and a laser metal cutter. The response needs to be in HTML format with specific tags like

,

- ,

- , etc.

First, I should make sure I understand all the requirements. The keywords are “laser cutter machine” and “laser metal cutter,” so those need to be prominently featured. They want unique descriptions highlighting features and benefits, using professional language. Each description should be distinct, avoiding any markdown.

I’ll start by outlining the structure. Maybe begin with an introduction paragraph, then a list of features, followed by sections on technical specs, applications, and benefits. Using tags for emphasis will make key points stand out. I need to include bullet points for lists using

- and

- .

Thinking about the content, what makes a laser cutter machine unique? High precision is a big one—laser cutting is known for accuracy. Then, speed, especially compared to traditional methods like plasma or oxy-fuel. Versatility in materials is another point; it can cut various metals and thicknesses. Also, energy efficiency and low maintenance costs are important selling points.

For the technical specifications, I’ll include things like power range, cutting speeds, maximum material thickness, beam quality, repetition rate, software compatibility, and cooling systems. These details add credibility and show that it’s a robust machine.

Applications should cover different industries—prototyping, manufacturing, aerospace, automotive, etc. This shows the machine’s versatility. Then, highlighting benefits like cost-effectiveness, precision, reliability, reduced material waste, high-speed production, safety features, low maintenance, and user-friendly interfaces will appeal to potential buyers.

I also need to ensure that each paragraph is concise and uses professional terminology without being too jargon-heavy. The language should engage the reader by emphasizing how this product solves their problems or improves their workflow.

Now, putting it all together, I’ll start with an introductory

tag, then a

- list for features. Next, technical specs in another

- Premium Quality Laser Source: Equipped with a high-power laser source that ensures precise and clean cuts on various materials, including steel, stainless steel, aluminum, and more.

- High Precision Cutting: Achieve micron-level accuracy with our advanced beam control system, ensuring minimal material waste and superior finished products.

- Superior Speed: Cut through thick materials at unprecedented speeds, reducing production time while maintaining exceptional quality.

- Versatile Material Compatibility: Capable of cutting a wide range of metals and thicknesses, making it ideal for diverse industrial applications.

- Energy Efficiency: Designed with energy-saving features to reduce operational costs without compromising performance.

- User-Friendly Interface: Intuitive control panel and software integration simplify operation, even for first-time users.

- Laser Power: Up to 2000W (adjustable depending on material thickness)

- Cutting Speed: Up to 60m/min (depending on material and thickness)

- Maximum Material Thickness: Stainless Steel – 30mm, Carbon Steel – 40mm

- Laser Beam Quality: M2 < 1.2 for superior cutting precision

- Repetition Rate: Up to 50kHz for consistent and accurate cuts

- Software Compatibility: Supports industry-standard CAD/CAM software for seamless workflow integration

- Cooling System: Advanced cooling technology ensures optimal laser performance and longevity

- Prototyping: Rapid production of high-precision prototypes with minimal setup time.

- Manufacturing: Mass production of intricate metal parts with consistent quality and accuracy.

- Aerospace & Automotive: Cutting complex shapes in lightweight metals for high-performance applications.

- Construction: Precision cutting of structural components for buildings and infrastructure.

- Cost-Effective: Low maintenance costs, long laser source lifespan, and minimal material waste ensure a fast return on investment.

- Premium Build Quality: Constructed with durable materials for years of reliable performance in demanding environments.

- Sustainable Operation: Energy-efficient design reduces power consumption while maintaining high productivity.

- , followed by applications and benefits sections each with their own lists. Finally, a conclusion that reinforces the value of the product.

I should double-check to make sure I’m not using markdown and stick strictly to HTML tags as specified. Also, ensure that each section is properly formatted without any markdown syntax slipping in.

Alright, time to draft the response step by step, making sure each element meets the user’s requirements.

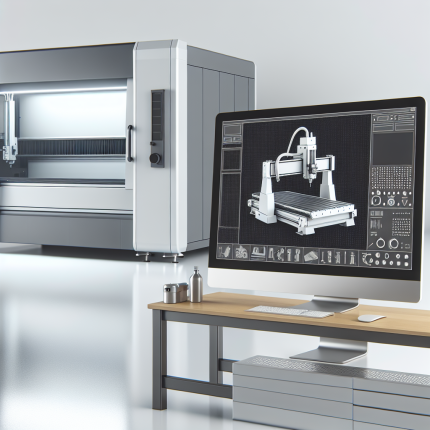

Introducing Our Advanced Laser Cutter Machine: Precision, Power, and Versatility Redefined

Our Laser Cutter Machine is a state-of-the-art solution designed for professionals seeking unmatched precision, speed, and reliability in material cutting. Whether you’re working with metals, plastics, or composites, this machine delivers exceptional performance, making it an indispensable tool for industries ranging from manufacturing to prototyping.

Key Features of Our Laser Metal Cutter:

Technical Specifications:

Applications:

Why Choose Our Laser Cutter Machine?

Experience the Future of Metal Cutting Today!

Upgrade your production capabilities with our cutting-edge Laser Cutter Machine. Designed for professionals who demand precision, speed, and reliability, this machine is your ultimate solution for all metal cutting needs. Contact us today to learn more about how we can help you achieve exceptional results.

Previous product: metal laser engraving | fiber laser for engraving | Next product: laser cutter metal | cheap laser cutter

- .

Carol Zhang (verified owner) –

**Laser Engraver Experience in Custom Gift Shop**

**1. Specific Project Experience: Personalized Leather Goods**

– **Project Focus:** We specialized in custom leather goods, such as personalized wallets and journals, which were in high demand among our customers seeking unique gifts.

– **Material Behavior & Results:** The laser engraving process on leather produced a sleek, burnished finish that added a touch of elegance. Intricate designs with fine details were executed smoothly, enhancing the product’s appeal.

– **Challenges & Solutions:** Ensuring consistent depth across thicker leather pieces was challenging. We adjusted laser settings, balancing power and speed to avoid scorching while achieving sharp, even engravings.

**2. Technical Performance: Power, Precision, and Software**

– **Power & Precision:** The laser’s adjustable power allowed precise control, crucial for delicate materials like leather. It delivered high-quality engravings without overheating the material.

– **Software Experience:** Utilizing vector graphics software provided flexibility in designing complex patterns. The user-friendly interface simplified workflow, with features enabling adjustments to optimize engraving outcomes.

– **Special Features:** The laser’s large bed size accommodated bigger projects, and a cooling system ensured safe operation, reducing risks of burns or discoloration.

**3. Business/Creative Impact: Workflow and Customer Feedback**

– **Workflow Improvement:** The laser engraver significantly sped up production, allowing us to handle more orders efficiently. It streamlined our process compared to previous manual methods, enhancing productivity.

– **Customer Feedback:** Customers appreciated the high-quality, personalized items, leading to positive reviews and repeat business. Custom wedding favors were particularly popular, with customers valuing the unique touch.

– **Return on Investment:** The machine paid for itself quickly through increased revenue and reduced material waste, making it a cost-effective addition to our shop.

**4. Comparison & Value: Advantages Over Previous Tools**

– **Comparison:** Transitioning from hand-engraving and manual tools, the laser offered superior precision, speed, and consistency. It minimized labor and time, allowing us to take on more projects.

– **Cost-Effectiveness:** Initial investment was offset by long-term savings in reduced material waste and faster turnaround times, making it a valuable asset for our business growth.

In summary, integrating the laser engraver into our workflow transformed our custom gift shop, enabling us to create high-quality, personalized products efficiently and effectively.

Wei Tanaka –

“Exceptional laser engraver! Impressive precision & detail in every cut. User-friendly software & intuitive controls boost productivity. Fast, reliable, and solidly built—a true workhorse. Highly recommend!”