How to Use Borax in Your Laser Engraver: A Step-by-Step Guide

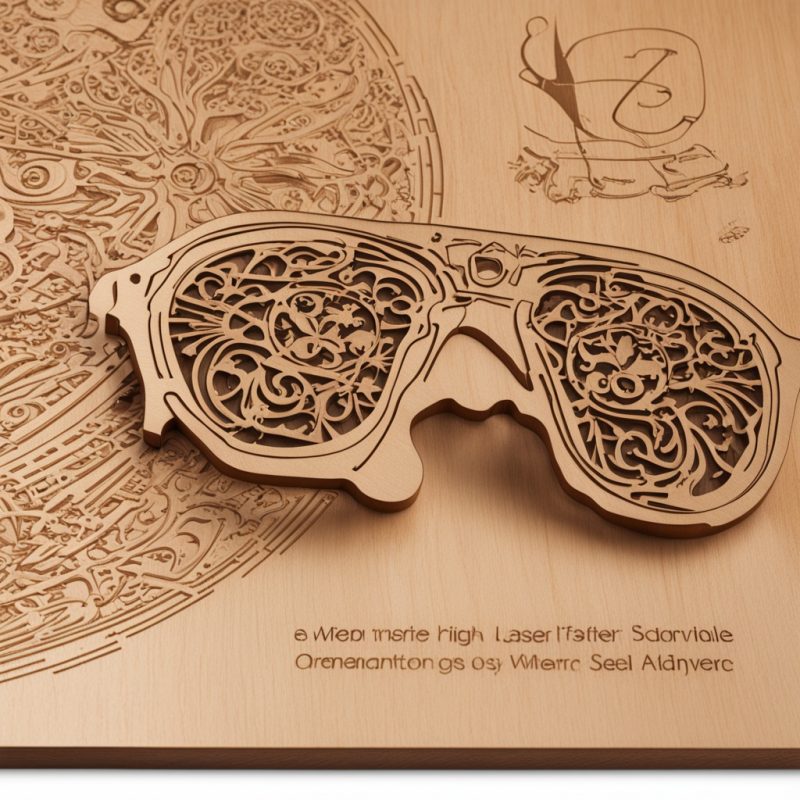

Laser engraving has become a popular method for creating intricate designs on various materials. Whether you’re working with wood, metal, or stone, achieving precise and clean cuts is essential. However, one often-overlooked aspect of laser engraving is the use of borax to enhance the quality of your work. In this article, we’ll explore how to use borax in a laser engraver effectively and safely. Whether you’re a professional or a hobbyist, understanding the role of borax can significantly improve your projects. Let’s dive in!

What is Borax and Why Use It?

Borax, also known as sodium tetraborate, is a naturally occurring mineral with a wide range of applications. In laser engraving, borax acts as a cleaning agent that helps remove residue and impurities from the surface being engraved. This ensures cleaner cuts and smoother finishes. But why exactly do you need to use borax in your laser engraver? Let’s consider a few reasons:

- Borax prevents discoloration and residue buildup on the material.

- It enhances the precision of the laser by reducing smoke and fumes during engraving.

- Borax helps maintain the longevity of your laser equipment by keeping it free from contaminants.

If you’re wondering, how does borax improve laser engraving quality?, the answer lies in its ability to act as a flux. By creating a protective layer on the material, borax ensures that the laser beam can penetrate cleanly without leaving unwanted marks or residues. This is particularly useful when working with metals like aluminum, stainless steel, and other reflective surfaces.

Preparing Your Laser Engraver for Borax Use

Before you start using borax in your laser engraver, it’s essential to prepare your equipment properly. Here are the steps to ensure a smooth experience:

- Clean your laser engraver thoroughly. Remove any dust or debris from the machine and the work area.

- Ensure that your laser engraver is calibrated correctly for the material you’re working with.

- Check the manufacturer’s guidelines to confirm if borax is compatible with your specific laser model. Some lasers may have unique requirements or restrictions.

If you’re unsure about compatibility, consider reaching out to the manufacturer or consulting online resources. For example, the how to use borax in laser engraver guide provides valuable insights into safe and effective practices.

Step-by-Step Guide: Applying Borax in Laser Engraving

Now that your laser engraver is ready, let’s walk through the process of using borax:

- Dilute borax solution correctly. Mix one tablespoon of borax powder with a cup of warm water. Stir until fully dissolved.

- Apply the solution evenly to the surface of your material using a clean cloth or brush. Avoid over-saturating the material, as this can lead to uneven results.

- Allow the borax solution to sit on the material for about 10 minutes. This gives it time to penetrate and prepare the surface.

- Wipe off any excess solution with a dry cloth before starting your engraving process.

By following these steps, you’ll ensure that the borax effectively cleans and prepares your material for laser engraving. This preparation step is particularly crucial when working with materials prone to residue buildup, such as plastic or certain types of stone.

Tips for Using Borax in Laser Engraving

To maximize the benefits of using borax in your laser engraver, here are some additional tips:

- Always work in a well-ventilated area. Borax fumes can be irritating if inhaled for extended periods.

- Test your setup on a small piece of material before starting your final project. This helps you adjust settings and ensure the best results.

- Store borax powder in an airtight container to prevent moisture absorption, which can affect its effectiveness.

If you’re curious about how often you should use borax, the answer depends on your project’s requirements. For frequent use, applying borax every few engravings is ideal. However, for smaller projects or less demanding materials, you might not need it as frequently.

Safety Precautions When Using Borax

While borax is generally safe to use, taking proper precautions is essential to protect yourself and your equipment:

- Wear protective gloves and eyewear when handling borax powder or solution.

- Avoid inhaling borax dust by using a mask or working in a well-ventilated area.

- Keep borax away from children and pets, as it can be harmful if ingested.

If you’re still unsure about how to safely use borax, consulting the how to use borax in laser engraver guide can provide additional guidance and best practices.

Frequently Asked Questions About Borax in Laser Engraving

Here are some common questions about using borax in your laser engraving projects:

- Is borax toxic? Borax is mildly toxic and should be handled with care. Avoid ingestion or prolonged skin contact.

- Can I reuse the borax solution? Yes, but it’s best to discard it after a few uses to prevent contamination and reduce effectiveness.

- What are alternatives to borax? For those who prefer not to use borax, alternatives like baking soda or commercial laser cleaning solutions can be effective in some cases.

If you’re considering how to substitute borax in your projects, experimenting with these alternatives is a good starting point. However, keep in mind that each option may have its own set of benefits and drawbacks.

Conclusion

Incorporating borax into your laser engraving process can lead to cleaner, more precise results while protecting your equipment from residue buildup. By following the steps outlined in this guide and adhering to safety precautions, you can enhance your projects and achieve professional-grade outcomes. Remember, if you’re ever unsure about how to use borax effectively or safely, consulting resources like the how to use borax in laser engraver guide is a valuable way to ensure success.

With practice and experimentation, you’ll become more confident in using borax to take your laser engraving projects to the next level. Happy creating!