Exploring the Capabilities of Laser Cutter Metal Machines

Laser cutter metal machines have revolutionized the manufacturing industry by offering precise, efficient, and versatile cutting solutions. These machines are essential tools for businesses looking to streamline their production processes and achieve high-quality results. In this article, we will explore the features, applications, and benefits of laser cutter metal machines, as well as answer some common questions about their use and maintenance.

What Is a Laser Cutter Metal Machine?

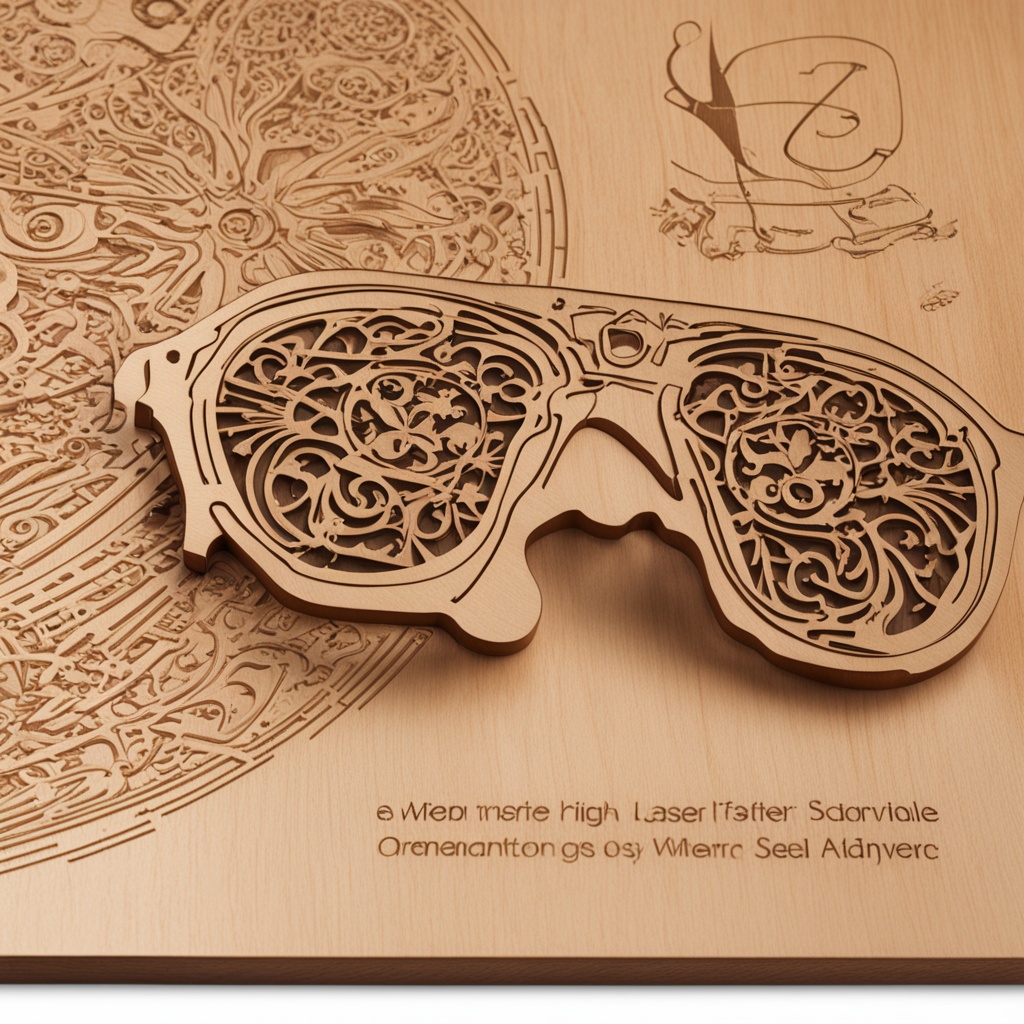

A laser cutter metal machine is a precision tool designed to cut, engrave, or etch various materials using a focused beam of light. The most common type used for metals is the diode laser, which generates high-powered beams capable of melting or vaporizing the material being cut. This technology allows for intricate designs and complex shapes that would be difficult or impossible to achieve with traditional cutting methods.

One of the standout features of these machines is their ability to work with a wide range of materials, including steel, aluminum, titanium, and other alloys. They are also compatible with non-metallic materials like wood, plastic, and glass, making them versatile for different industries. For example, in the automotive sector, laser cutter metal machines are used to create custom parts, while in the jewelry industry, they enable the production of delicate engravings.

Applications of Laser Cutter Metal Machines

The applications of laser cutter metal machines are vast and varied. Some of the most common uses include:

- Cutting intricate patterns for architectural designs

- Creating decorative elements for furniture or home decor

- Producing precision components for machinery and equipment

- Engraving logos, serial numbers, or other markings on products

- Fabricating custom metal signs and plaques

These machines are particularly popular in industries that require high accuracy and repeatability, such as aerospace, electronics, and medical devices. The ability to produce consistent results ensures that even the most demanding projects can be completed with ease.

Advantages of Using Laser Cutter Metal Machines

There are numerous benefits to using laser cutter metal machines over traditional cutting methods:

- Precision and Accuracy: The focused laser beam ensures minimal material waste and highly precise cuts, even on complex designs.

- Speed and Efficiency: Laser cutting is much faster than manual or mechanical cutting methods, reducing production time and increasing output.

- Versatility: These machines can handle a wide range of materials and thicknesses, making them suitable for diverse applications.

- Cost-Effectiveness: Despite the initial investment, laser cutter metal machines offer long-term savings through reduced material waste and lower labor costs.

- Eco-Friendly: The process generates minimal dust or debris, making it a cleaner and more environmentally friendly option compared to other cutting methods.

These advantages make laser cutter metal machines an invaluable tool for businesses aiming to enhance their production capabilities while maintaining high standards of quality.

How Does a Laser Cutter Metal Machine Work?

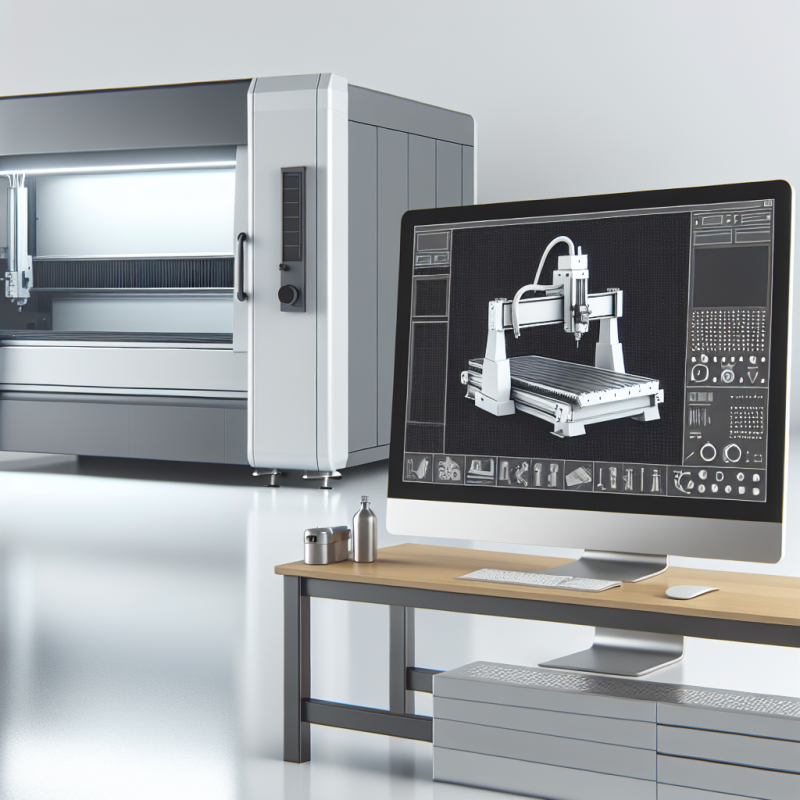

To understand how a laser cutter metal machine operates, let’s break it down into its basic components and processes:

- Laser Source: The machine uses a diode laser to generate a high-powered beam of light. This beam is focused through a lens or mirror system to create an intense point of energy.

- Material Handling: The metal sheet or workpiece is placed on a precision table, which can move in multiple directions to guide the laser beam accurately.

- Cutting Process: As the laser beam hits the material, it either melts, vaporizes, or blows away the molten material with a gas stream (such as oxygen or nitrogen). This creates clean, precise cuts without the need for physical contact between the machine and the workpiece.

- Control System: Modern laser cutter metal machines are equipped with advanced software that allows users to input designs, adjust settings, and monitor the cutting process in real-time. This ensures high precision and minimizes errors.

The combination of these components enables the machine to perform complex tasks with ease, making it a versatile tool for both small-scale projects and large-scale production runs.

Maintenance and Care for Laser Cutter Metal Machines

Like any precision tool, laser cutter metal machines require proper maintenance to ensure optimal performance and longevity. Regular cleaning of the lenses and mirrors is essential to prevent dust or debris from affecting the beam’s accuracy. Additionally, it’s important to monitor the machine’s cooling system to avoid overheating, which can lead to malfunctions.

Operators should also follow safety guidelines when working with these machines, such as wearing protective eyewear and ensuring adequate ventilation in the workspace. Proper training is necessary to maximize efficiency and minimize the risk of accidents or equipment damage.

Frequently Asked Questions About Laser Cutter Metal Machines

Q: Can laser cutter metal machines work with all types of metals?

A: While these machines are highly versatile, they may not be suitable for every type of metal. Factors such as thickness, hardness, and reflectivity can influence the machine’s performance. It’s important to consult the manufacturer or a professional before selecting a machine for specific applications.

Q: Are laser cutter metal machines easy to use?

A: With modern advancements in software and interface design, these machines are becoming increasingly user-friendly. However, some training is typically required to operate them effectively, especially for complex designs or large-scale projects.

Q: How much do laser cutter metal machines cost?

A: The cost of a laser cutter metal machine varies depending on its size, power, and features. Entry-level models can be purchased for a few thousand dollars, while high-end industrial units may cost hundreds of thousands of dollars. It’s important to weigh the initial investment against long-term savings in labor, material waste, and production efficiency.

The Future of Laser Cutter Metal Machines

As technology continues to evolve, laser cutter metal machines are likely to become even more advanced and accessible. Innovations such as AI-driven automation, cloud-based software integration, and improved energy efficiency are already being explored by manufacturers. These advancements will further enhance the precision, speed, and versatility of these machines, making them an indispensable tool for industries worldwide.

In conclusion, laser cutter metal machines offer a powerful solution for businesses seeking to improve their production processes. Their ability to deliver precise, efficient, and versatile results makes them a valuable investment for any operation that values quality and innovation. If you’re considering adding one of these machines to your workflow, it’s worth exploring the options available to find the best fit for your needs.